Speed and quality are two of the few things that can get a company ahead of its competitors. The challenge is accelerating the product development process to get ahead without compromising quality.

The speed-to-market mind set has gained momentum in part due to today’s quick pace of innovation and compounding technologies, accessibility to funding through platforms like Kickstarter where anyone can be your competition, and the way that consumers are being conditioned to instant gratification.

Though a product’s time-to-market is becoming increasingly more critical, caution must still be taken. Faster is not always better, especially if it means cutting corners, hastily producing a low quality product, or even producing the wrong product that is bound to fail in the market. There must be a balance between having a sense of urgency and maintaining high-quality design practice standards.

How is this done? Let’s examine a few of the steps that can help reduce time-to-market and accelerate your product development process.

Create a Well-Defined Product Development Strategy

A smooth development process begins with having a product development strategy. An ideal strategy will detail each necessary step from product design to product launch. This starts with ensuring your vision is clearly defined. What is the purpose of your product? What problem will it solve? Is your product unique when compared to existing, currently-available products?

Have Focus

While you can certainly develop a product with speed, if it’s heading in the wrong direction it won’t get you anywhere. Be sure your actions stay in line with your overall strategy. There may be changes along the way, but do not get distracted by ideas or features that are not linked to the essence of your product. Wanting to include every possible feature into your product is natural, but attempting this, especially at the product’s conception, may overload the amount of time and resources you currently have available. Simplifying is a much more effective approach. Consider first developing a base product, then plan for future follow up projects that will expand functionality and reach new markets. This is the essence of a good product platform strategy.

Fix a Time Frame

Determining a reasonable product-release time frame is imperative to keeping your project on track. Try building a workable timeline with key developmental milestones along the way. This type of planning can better progress product development through accountability, and keeping a sense of urgency and focus.

This is where having the right team can make all of the difference. Allocating tasks to skilled and experienced people decreases the chance of large bumps down the road. A timeline keeps your entire team working towards a coordinated end goal. However, having a single team member out of sync could threaten an on-time release date, which could put you behind the competition. If effective resource allocation or coordination turns out to be an issue amongst your own team, consider partnering with external experts to help you eliminate steps and streamline your process.

Design for Manufacturing (DFM)

A successful product design goes beyond a unique idea that looks good on paper. It must also be manufacturable, as well as functional once it is produced. DFM is a critical step in a new product’s design, manufacturing tooling design, and process development. If done well, DFM will ensure both quality and productivity.

Design for Your Market

After all of the effort, time, and money of making your product, will anyone buy it? Key market research can help draw valuable conclusions that influence your design concept. For example, though top-of-the-line materials may look more impressive and give your product a high-end feel, they will also drive up your costs. In turn you will need to sell your product at a higher price point in order to make a profit. However, if your market is only willing to buy your type of product at a moderate price, a higher price point could severely limit your possible sales. This is why for a successful product it’s important to keep your market in mind from the start. Basing your design requirements on known customer needs will better calibrate your product for your target market.

Be Agile

Throughout the product development process a number of obstacles may come about. Some of them will be expected, but many of them inevitably will not be, for even the most well-planned product development processes. Agility means having the ability to quickly and easily move or think. Your team must be able to expect, recognize, assess, and react appropriately to any new variables that come into play. Such a team has a much better chance of successfully navigating through obstacles.

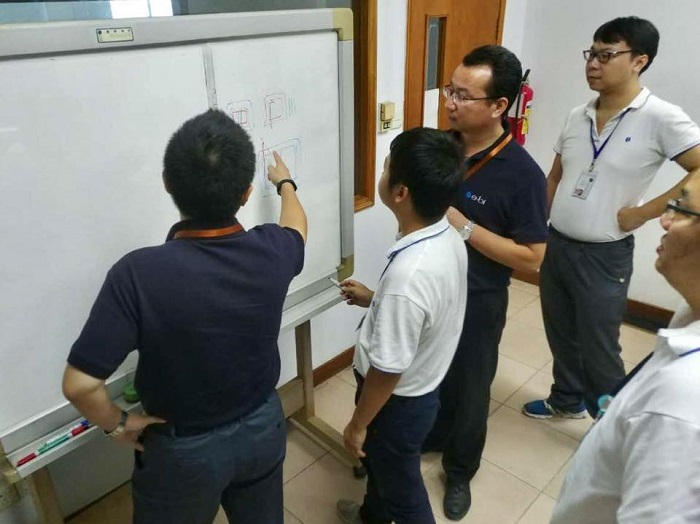

Having a team with a broad range of expertise (engineering, sales, design, marketing, etc.) is an excellent way to prepare for unknown issues. Leveraging their diverse skillsets will help you overcome the hurdles which may arise at any point in the product development process.

Another defining characteristic of an agile team is good communication. This includes straightforward person-to-person communication and having a system which ensures everyone clearly understands the project’s current status. The system should be a platform which allows teams to both track the project’s progress, and proactively communicate any current issues, updates, and changes. Enhancing team communication is one of the most effective ways to generate timely decision making and minimize product development delays.

Periodic Testing

Certainly no one would argue that during product development it would be better to catch any issues sooner rather than later. It is much easier, less time consuming, and more cost effective to fix an issue shortly after it occurs than to wait until a product is finished. Waiting to correct a problem allows it to compound into a much more costly, prolonged issue. For example, a situation requiring three weeks and $6,000 of re-tooling may seem like an expensive, unacceptable setback when it is first discovered. Though temporarily painful, correcting the issue right away may save you from a possible total product recall in the future. The required re-tooling is now accompanied by additional shipping fees, late deliveries, and negative reviews, the combination of which could prove catastrophic to your business.

To avoid a similar scenario, your product should be tested at critical intervals throughout the development process. This will give you multiple chances to catch and deal with issues as early in the development process as possible. Including periodic testing in your strategic plan will help minimize backtracking and keep your project looking forward.