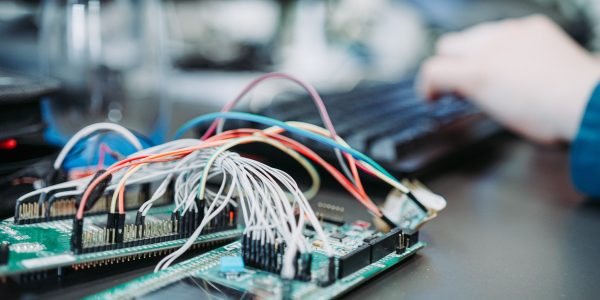

ELECTRONICS ASSEMBLY

Expert Manufacturing Outsourcing

The main activity of our electronics division is the provision of manufacturing outsourcing, or in other words, manufacturing for third parties through the application of product-specific systems and levels of quality. Our electronics specialists work with a network of quality electronics factories to make sure your electronic components come together seamlessly. We are experienced in a wide range of capabilities including, but not limited to those listed below.

Capabilities

PCB Capabilities

Thin PCB

Flex PCB

Flex Hybrid PCB

High Density Layer PCB

Thick PCB (Powerboard)

Odd Form Placement

65mm tall

Cut clinch

100N force insertion

Tape, Tray, Bowl, Radial, Axial supply type

Post Process

Conformal coating

PCBA programming

PCBA functional testing

Final assembly

Packaging

Certification

SMT Capabilities

Up to 184,800 CPH per single machine—-machines are quick

Smallest component size 0201 metric

Largest 150 x 25 x 50 mm or Component diagonal 150 mm or less

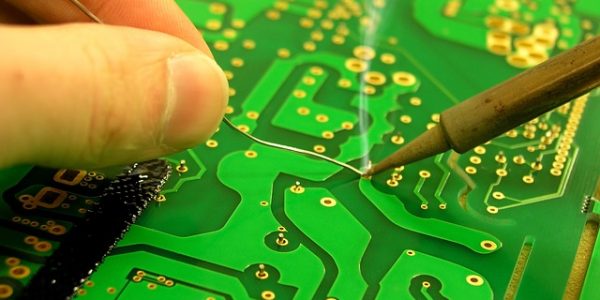

Solder Capabilities

Specs of Screen Printer – 15 second print time (0201 (Metric) aperture, 2mm lead/ball spacing, 15mm ball diameter)

Lead free

Lead

Selective Solder

Wave Solder

Hand Solder

PCB Handling

50×50 to 610x1500mm

3 to 9mm thick

Quality

Solder Past Inspection 2D/3D (SPI)

Automated Optical Inspection (AOI)

X-Ray

MES system for full traceability

Sampling of Product Types

Power supplies

Industrial controls

RFID products

PCBA

PCBA boards

Cables

Wire harness

And more