PROTOTYPING

Engineering Support for Prototype Manufacturing

The prototype stage is an early test of the manufacturability of product design, cost, equipment set-up, and process development. It is also a design debugging process, which requires intensive industry expertise. E-BI’s leading industry experts from different engineering backgrounds can help to solve problems and provide better solutions for a fast delivery of your prototype.

The goal of making a fast prototype is to evaluate the original ideas of innovation, and to offer a physical example of what the product will eventually be. Multiple versions of prototypes may be required in order to reach the final version that is acceptable by the clients. The ideal prototype should achieve the WOW factor in terms of form, technology, and cost.

E-BI offers a wide range of prototype manufacturing from initial industrial design mock-up, to trade show level high quality prototypes that can be used to attract orders. With our Star Factory Alliance members, we offer specialty mechanical, electrical, electronics, metal bending, welding, plastic, packaging, and cut and sew prototypes. From napkin idea sketches to formal ID design, our engineering team can help to finalize design to make the ideal prototypes that speed up the product design cycle.

Product Rendering/Virtual Prototyping

Visual prototyping is generating product images based on industrial design and initial mechanical design. These images provide a real “look” at what a product may look like when finished, before future resources are committed such as design, tooling, and other operation costs. They are a great reference for a marketing team to evaluate the look and feel of a new-born product.

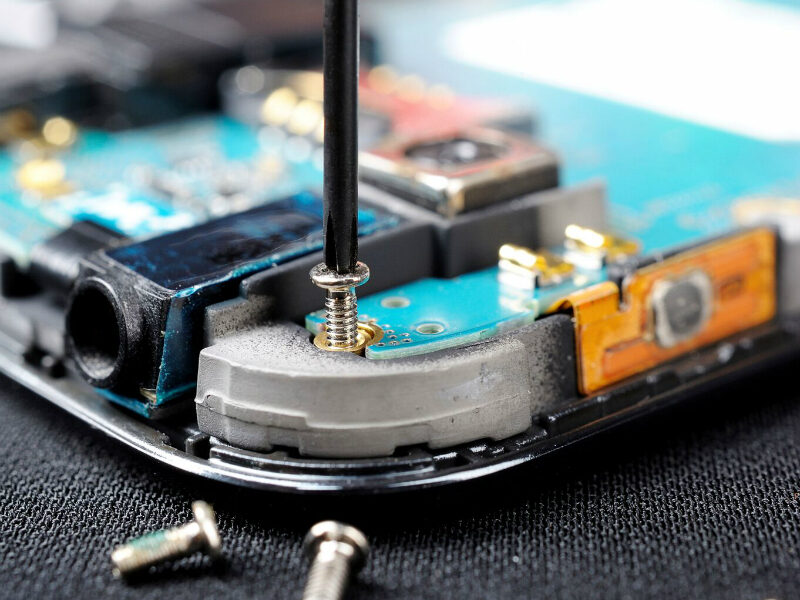

Electronics Product Prototyping

Electronics prototyping involves PCBA, firmware, system integrations, display, power, testing, BOM generation, and associated mechanical parts manufacturing. From breadboard level to the finished product level, E-BI can help to get the testing version made according to the design.

Retail Package Prototyping

Packaging serves many purposes for consumer products. It protects the product, attracts and informs consumers, and assists at the point of sale. Therefore, a compelling packaging design is of great importance. From cardboard level to sophisticated high-end molded packaging, E-BI offers a wide variety of package prototyping. Our designers analyze the packaging concept to ensure complete form, fit, and function for your product.

Mechanical Product Prototyping

Mechanical product prototyping covers a wide variety of technologies and the manufacturing process depends on actual product requirements. It can be divided into two categories: structural parts and surface finish.

Structural Parts:

For a prototype, the structural parts are made by CNC milling, CNC tuning, metal bending, stamping, SLA, chemical etching and other processes. Prototype production is optimized to use less or permanent tooling to save on cost. However, intensive programming and plenty of production time is required for CNC machines to machine out parts from raw material blocks. Sometimes even temporary molding tools are needed to create a specially designed shape.

Surface Finish:

In order to get the closest touch and feel between prototypes and finished products, a surface finish is always the most demanding process. This process may include: pad printing, laser engraving, brushing, electro-plating, anodizing, passivation, black coating, phosphating, sanding and polishing, blasting, color matching, painting, UV coating, and powder coating.