E-BI Rapid Prototype Manufacturing

A “killer product” represents a fine-tuned solution, or a “recipe”, that better addresses a specific market need. We call it a recipe because it has to consist of the “right proportion” of all “ingredients”, such as a product’s form factors, functions, costs, and services that solve the itching needs of clients. Any out-of-proportion design will lead to product failure. Thus, the “recipe” development has become the key to success. To fine-tune the recipe, prototyping is the fastest and easiest way to start. At a minimal cost, a high-quality prototype can validate the new “recipe” from a multidimensional angle. E-BI can help to get prototypes made with global sourcing.

The Recipe

The first step before prototyping is product concept design, which lays the foundation of the new recipe. The second step is engineering design that materializes this concept. Good engineering design needs to be supported by manufacturability, material resources, and proper cost.

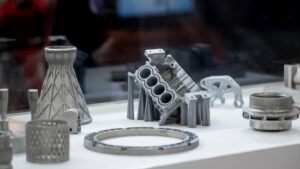

Following up the engineering design is prototype manufacturing. Depending on the product, a prototype can be simple or very complex with the integration of cross-discipline technologies such as electronic hardware, firmware, plastics, metal formation, and casting. Integrations of these different processes in a short period can be a major challenge. With 20+ years of accumulated experience, E-BI specialty teams can help.

Prototyped-based EVT and DVT processes have been popular for concurrent engineering projects on a global scale. As part of the NPI process, all key “recipe” parameters are being evaluated such as touch and feel, performance, and cost of manufacturing. Optimization of the product recipe is done during this period. High quality and fast turn-around of prototypes are key for product recipe development speed, and a successful product launch. With the prototype, both consumer experience and field tests can be implemented at a very early stage.

The Results

Developing a killer product recipe is magic. With E-BI’s specialty teams on electronics, metal, plastic molding, casting, testing, soft goods, and packaging we can deliver value-added prototypes that help to accelerate the process from worldwide manufacturing resources, even during the pandemic restrictions. From manufacturing process development to function tests, E-BI can offer rapid prototype solutions that assure faster product launches.[/vc_column_text][/vc_column][/vc_row]