In the fast-paced world of global commerce, the efficient transportation of goods is crucial. Among the various modes of transportation, air cargo stands out for its speed and reliability. However, ensuring the safe delivery of products via air freight involves navigating a myriad of challenges, with temperature and pressure being two critical factors that can significantly impact the integrity of shipped goods.

Temperature fluctuations during air cargo transit can pose a substantial risk to various types of products, ranging from perishable foods to sensitive electronic devices. Extreme temperatures, whether hot or cold, can compromise the quality and safety of goods, leading to spoilage, damage, or even total loss. For instance, perishable items such as fruits, vegetables, and pharmaceuticals require specific temperature ranges to maintain their freshness and effectiveness. Deviations from these optimal conditions can result in significant financial losses for both suppliers and buyers.

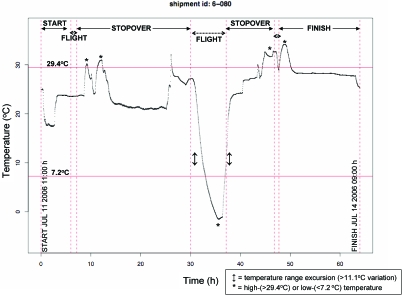

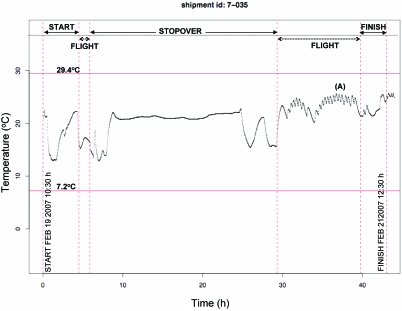

The charts below show examples of the temperature fluctuations in the cargo area during an international shipment depending on the weather conditions.

^International shipment during hot weather with both high-temperature excursions (during stopovers) and low-temperature excursions (in flight). Source

^International shipment during cold weather, demonstrating the use of heated cargo hold (A). Source

Similarly, pressure changes experienced during air travel can also affect the quality and integrity of products. As aircraft ascend to higher altitudes, the atmospheric pressure decreases, leading to a decrease in the pressure inside the cargo hold. This reduction in pressure can impact certain goods, especially those that are sensitive to changes in air pressure, such as electronic components or products packaged in sealed containers. For instance, sealed containers may experience pressure differentials that can cause them to expand or contract, potentially leading to leaks, breakage, or other forms of damage.

To mitigate the risks associated with temperature and pressure fluctuations, various measures can be implemented throughout the shipping process:

- Advanced Packaging Solutions: Utilizing specialized packaging materials such as insulated containers, thermal blankets, and temperature-controlled packaging can help maintain the desired temperature range for sensitive products. These packaging solutions act as a barrier against external temperature variations, safeguarding the contents during transit.

- Temperature Monitoring Systems: Incorporating temperature monitoring devices within cargo shipments allows real-time tracking of temperature conditions throughout the journey. These systems provide visibility and enable proactive measures to be taken in case of deviations from the optimal temperature range, such as adjusting the cargo hold settings or rerouting the shipment if necessary.

- Pressure Equalization Techniques: Employing pressure equalization techniques within packaging or containers can help minimize the effects of pressure differentials during air travel. Ventilation systems or pressure-relief valves can help balance the internal and external pressures, reducing the risk of damage to sensitive products.

- Regulatory Compliance and Documentation: Ensuring compliance with relevant regulatory requirements and providing accurate documentation regarding temperature-sensitive products is essential for smooth customs clearance and adherence to quality standards. Proper labeling and documentation enable stakeholders to identify and handle temperature-sensitive shipments appropriately.

- Collaborative Partnerships: Establishing collaborative partnerships with experienced logistics providers who specialize in air cargo transportation can provide valuable expertise and resources for managing temperature and pressure challenges effectively. Working closely with trusted partners can enhance supply chain visibility and reliability.

In conclusion, the impact of temperature and pressure on products shipping via air cargo cannot be understated. As globalization continues to drive demand for fast and efficient transportation solutions, it is imperative for businesses to prioritize the implementation of robust strategies and technologies to safeguard their goods throughout the shipping process. By adopting proactive measures, leveraging innovative solutions, and fostering collaborative partnerships, stakeholders can mitigate risks and ensure the safe and timely delivery of products via air cargo, even in the face of challenging environmental conditions.